Part 1: Construction Kit

I told my roommate that I have to design clips for class and he said "what like paperclips" and I said "sure." I liked the aesthetic concept of a jumbo paperclip, and I thought I could use them functionally as chip bag clips or something in the future.

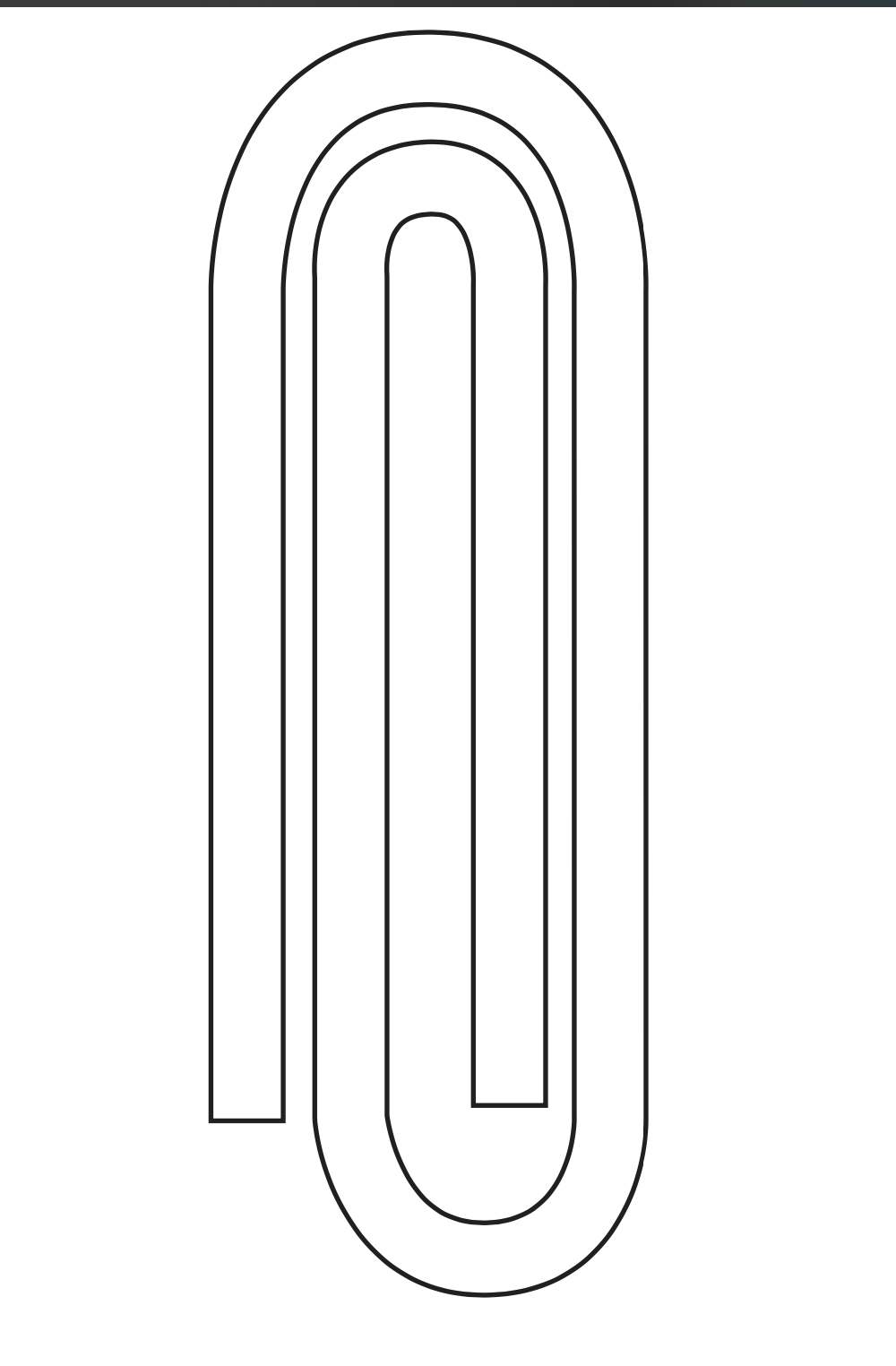

I started by designing a paperclip in illustrator.

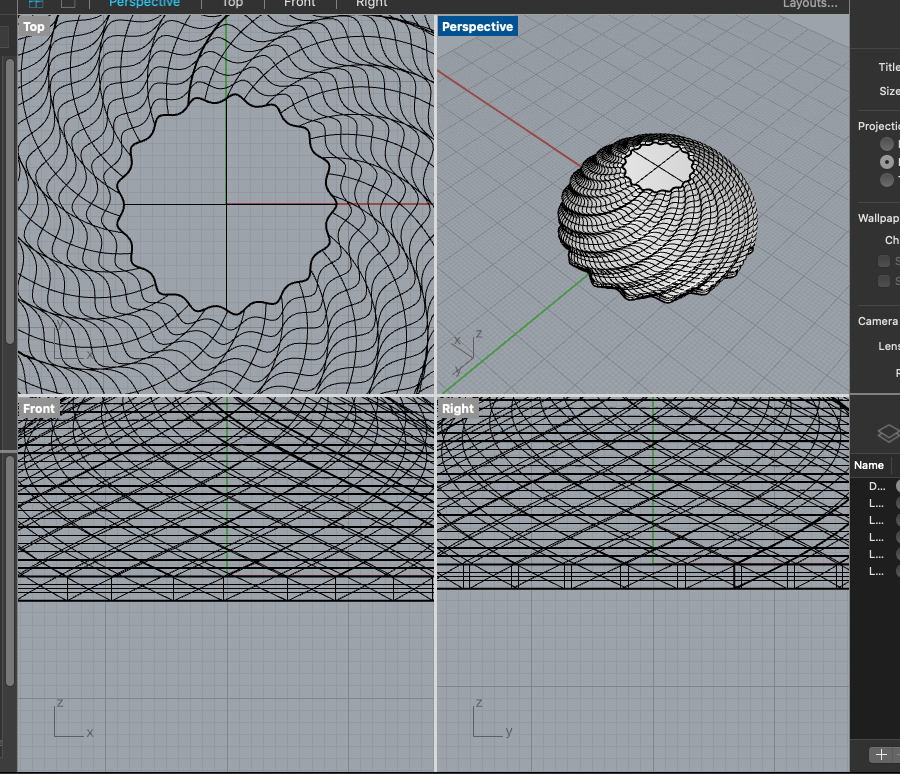

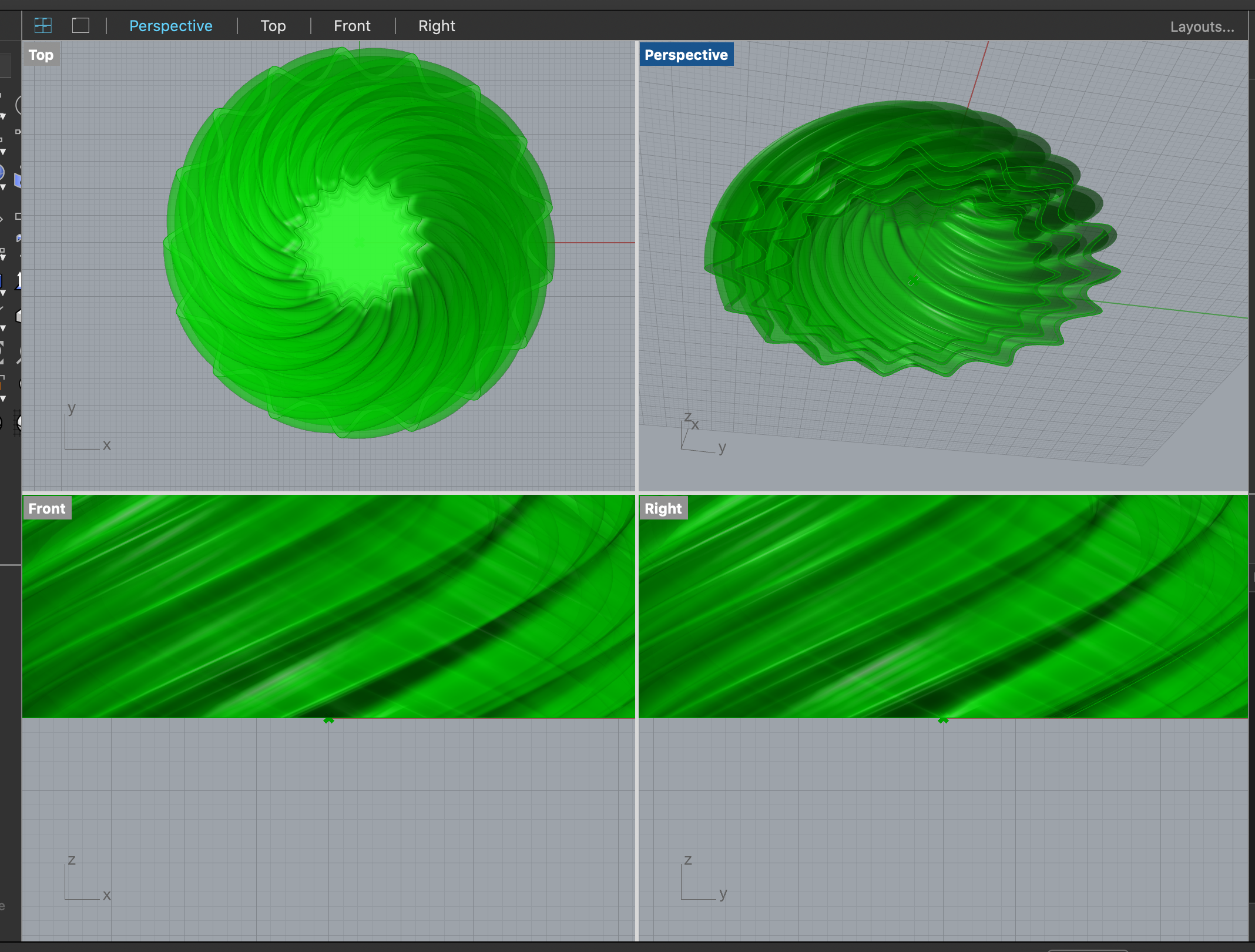

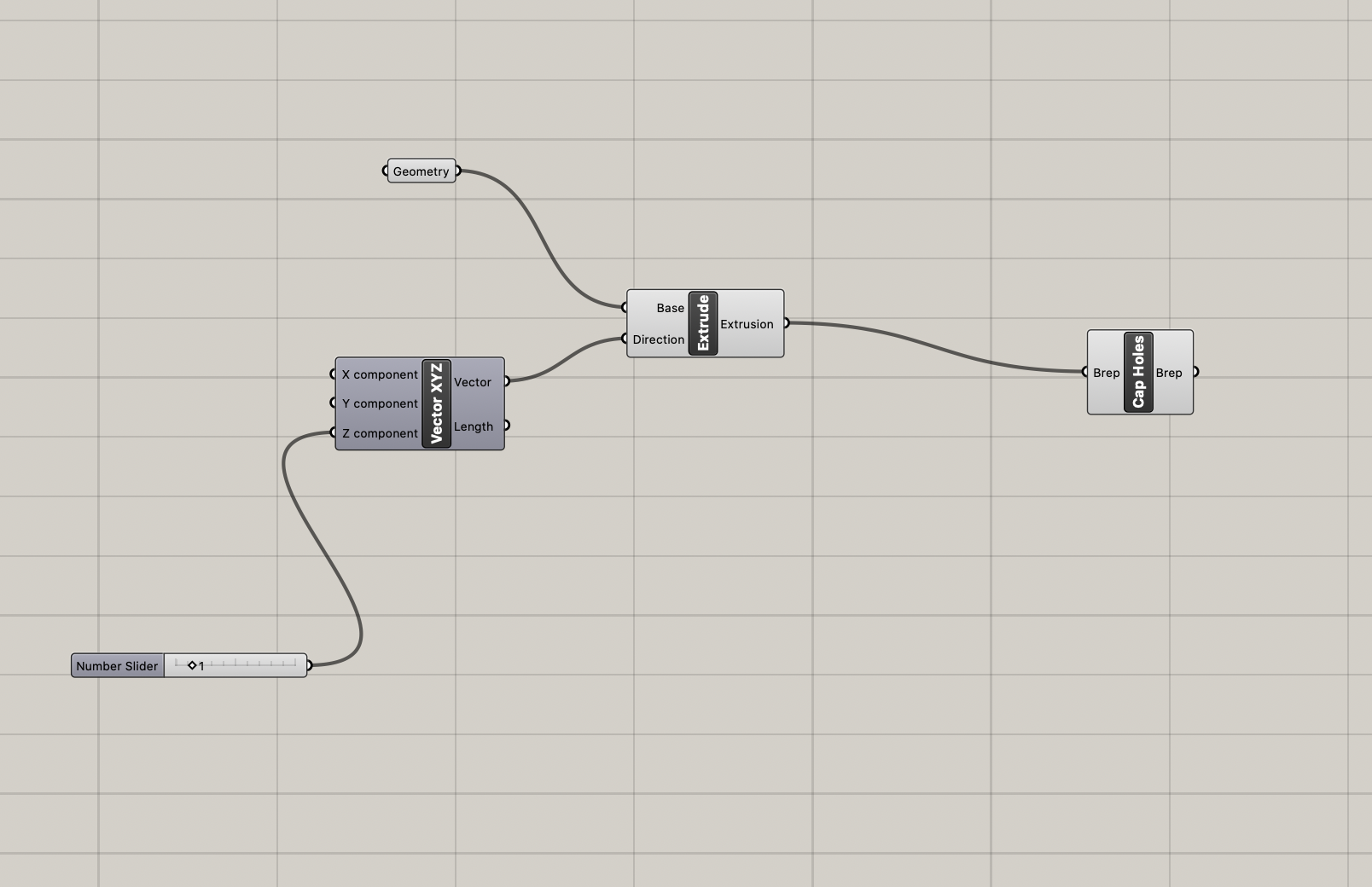

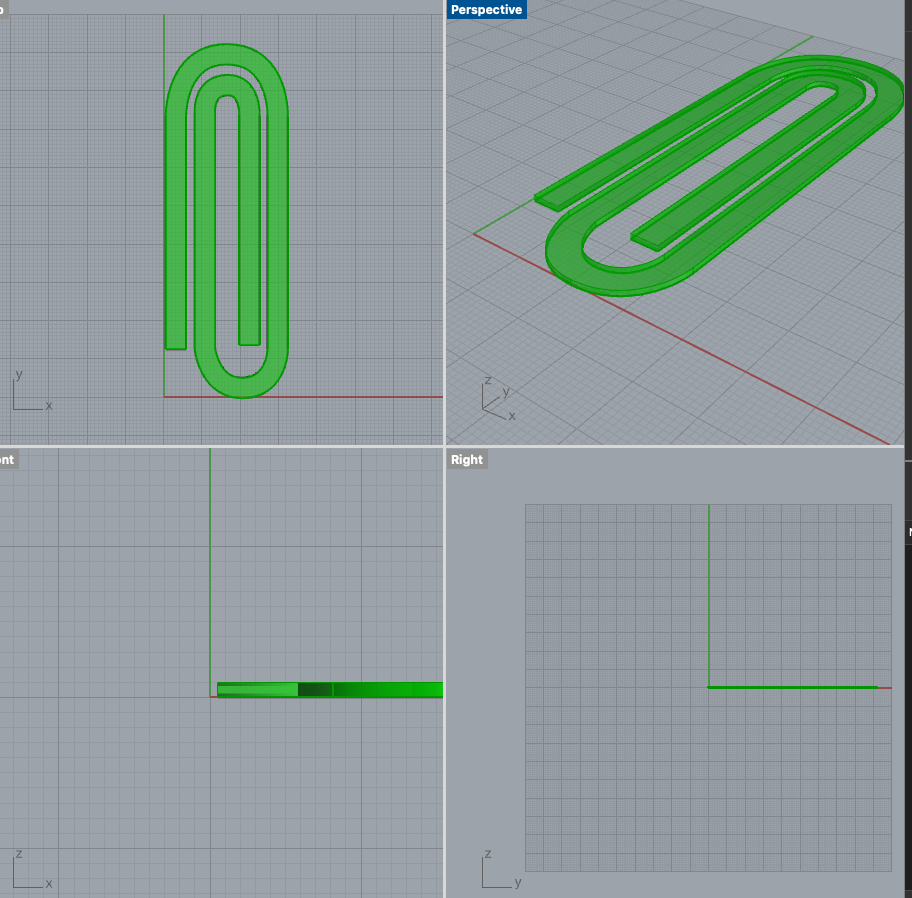

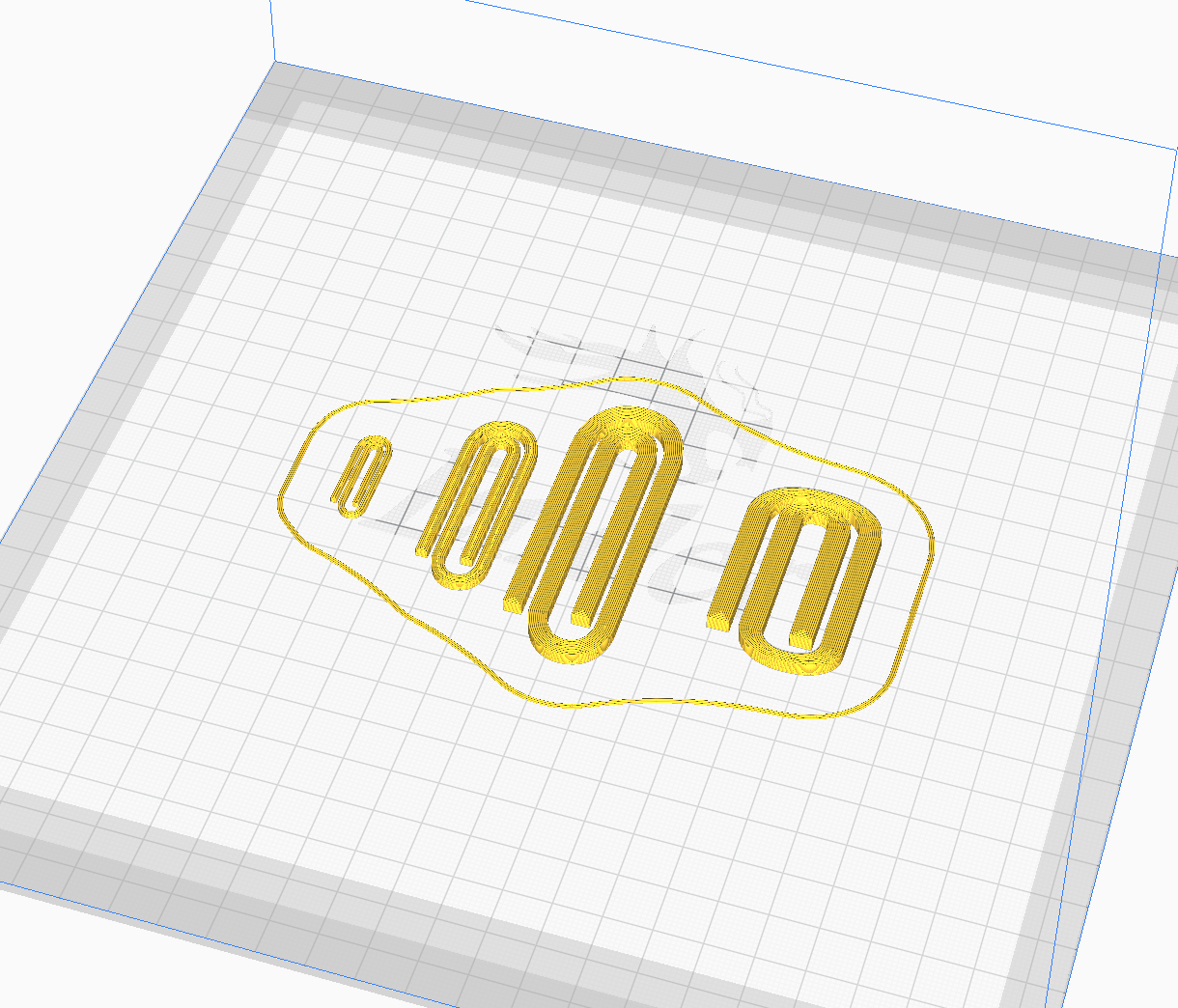

I then imported the curve to Rhino and started up grasshopper. I used visual programming to extrude the curve and cap holes to make an object.

Clip One

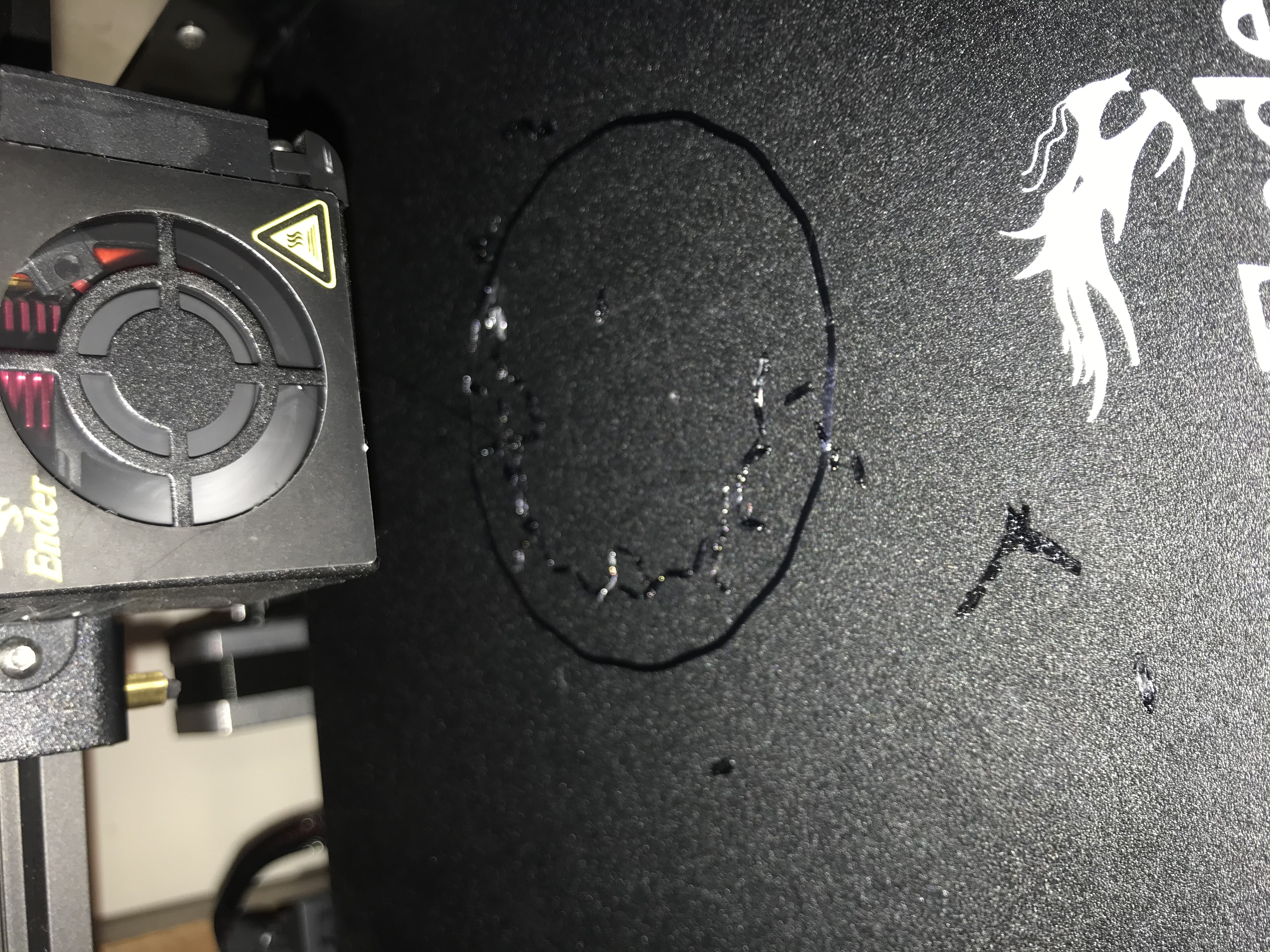

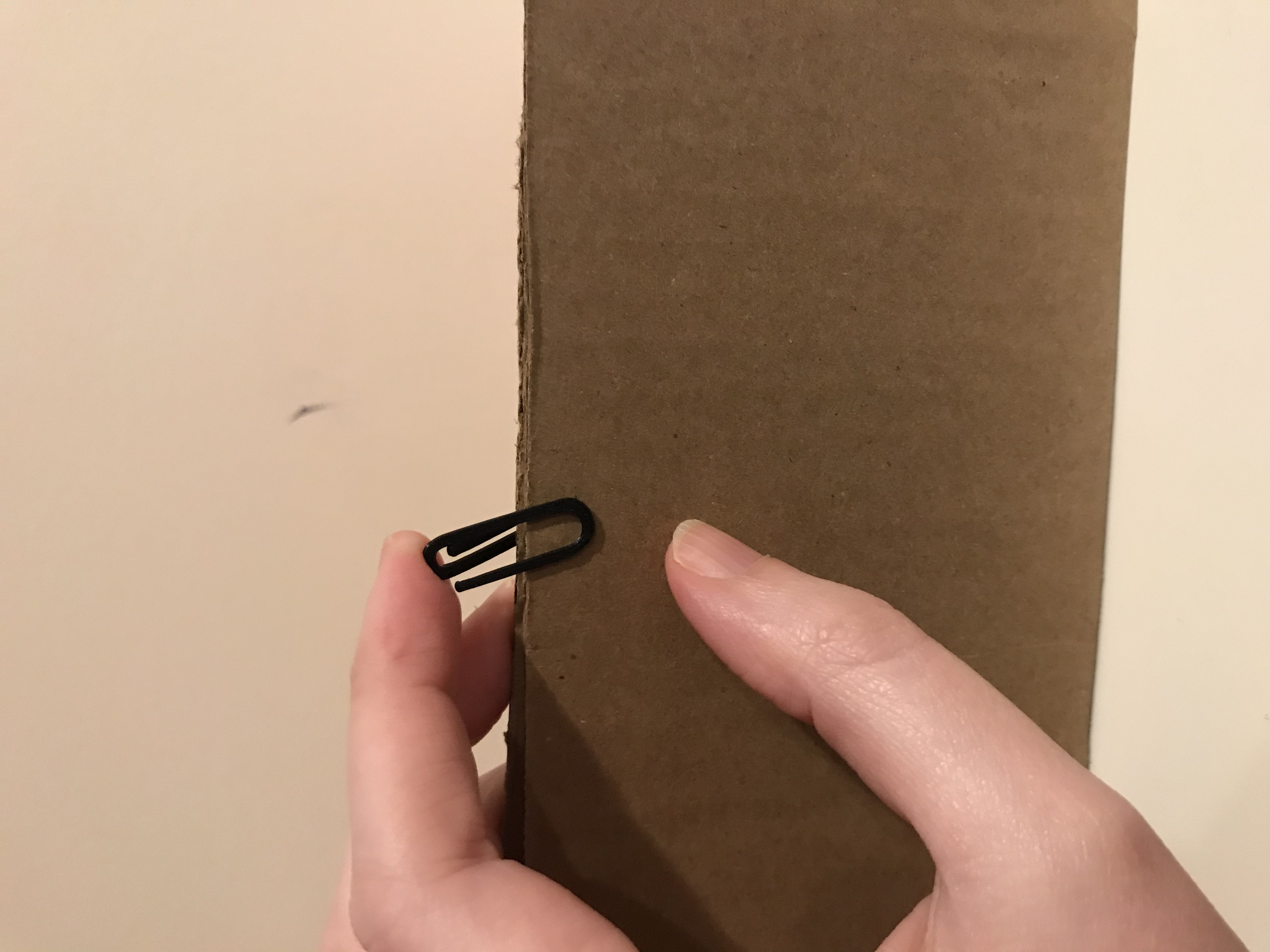

I wasn't really sure how flexible the plastic was going to be once printed, so this first clip was mostly a trial run to prototype. I started with a clip about 9cm long and 2mm high. My plan if the clip was too flexible was to increase the paperclip height to make the plastic more durable. My plan if the clip was not flexible enough was to add an angle to the inner loop of the clip so it could better accommodate the height of 2 pieces of cardboard.

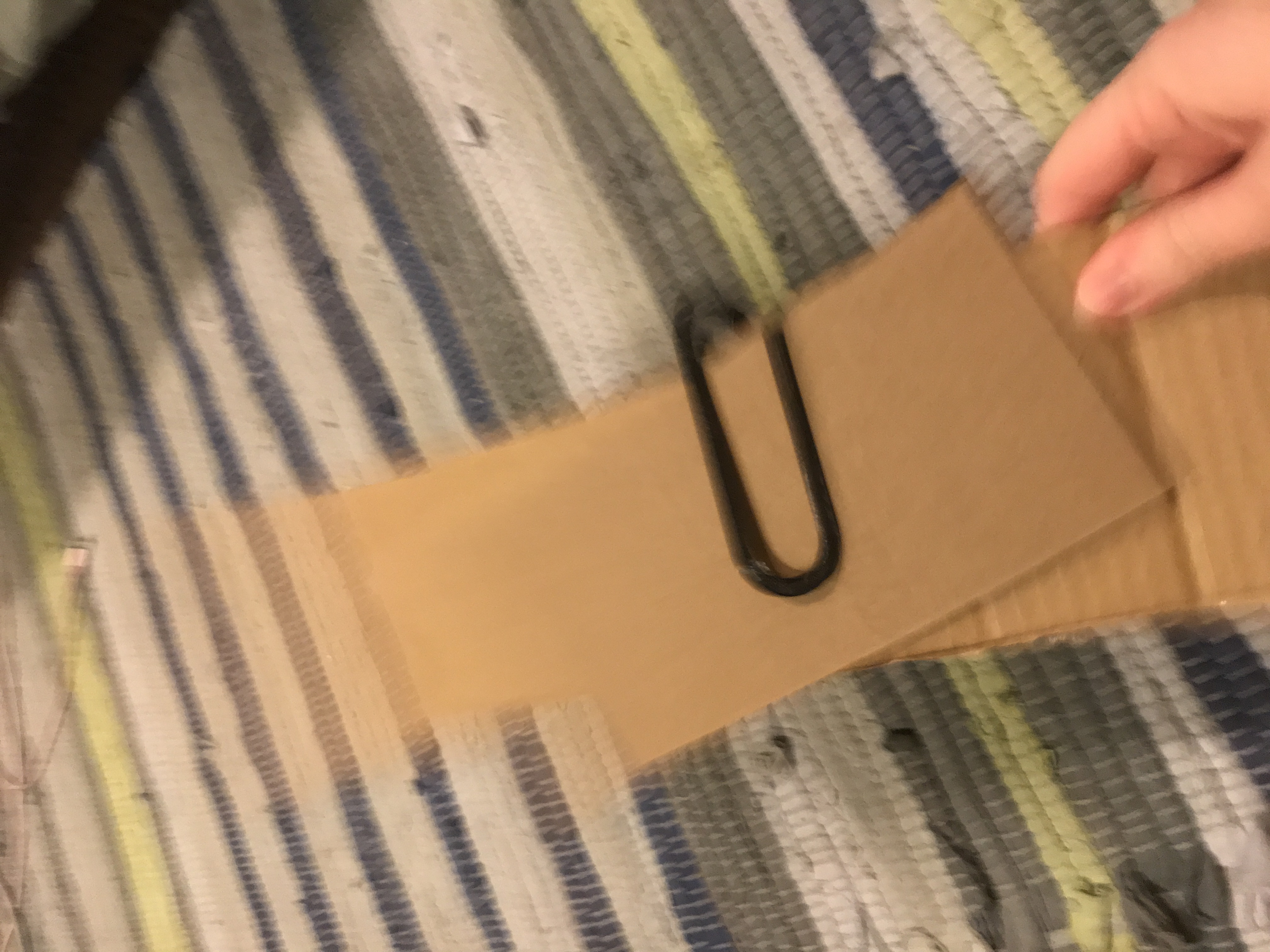

In testing the first clip, it turned out that it was too flexible and did not securely hold together the cardboard pieces.

Clip Two

I increased the height of the clip to 3mm using the number slider in grasshopper. I also changed the Cura slicer setting to make top/bottom pattern be concentric because I thought it would look better aesthetically.

This clip passed the shaking cardboard test!

Clip Three

I increased the height of the clip again to 4mm because I was curious if it would become too inflexible at that point. It was sturdier but was still able to clip the two cardboard pieces, so I actually liked this better than Clip 2.

Clips Four through Seven

Since I had already achieved my goal of securely clipping together two pieces of cardboard, I decided to experiment with different sizes of jumbo paperclips. I took my design for Clip 3 and scaled it uniformly at 75% (Clip 4), 50% (Clip 5), and 25% (Clip 6), then scaled just the x axis 50% (Clip 7).

Clip 6 turned out to be similar dimensions to an actual paperclip which was fun, but it and Clip 5 weren't strong enough to actually hold cardboard together. Clips 4 and 7 could hold cardboard, but I still preferred the sturdiness and jumbo-ness of Clip 3.

Clips Eight through Ten

I tried a couple of different xy scales while keeping the z size constant in order to maintain the sturdiness that I preferred from Clip 3. Clip 8 was 50%, Clip 9 was 75%, and Clip 10 was the same since I liked it. All three clips were able to hold cardboard together, although I noticed that Clip 8 had warped a little after holding the cardboard.